New approach to optimize high-quality 3D prints of soft materials

A typical optimization model or experimental design will focus on a few parameters that are considered most important to the print.

A team of researchers in Carnegie Mellon University's College of Engineering have designed the Expert-Guided Optimization (EGO) method to optimize high-quality 3-D prints of soft materials.

The researchers' Expert-Guided Optimization (EGO) method combines expert judgment with an optimization algorithm that efficiently searches combinations of parameters relevant for 3-D printing, enabling high-fidelity soft material products to be printed.

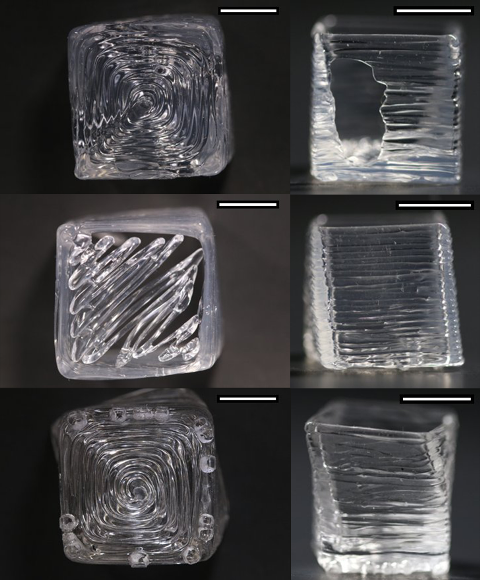

The research paper entitled "Expert-guided optimization for 3D printing of soft and liquid materials", demonstrate the EGO method using liquid polydimethylsiloxane (PDMS) elastomer resin, a material often used in wearable sensors and medical devices.

The researchers used a printing method called freeform reversible embedding (FRE), in which soft materials are deposited within a gel support bath. A typical optimization model or experimental design will focus on a few parameters that are considered most important to the print.

"When 3-D printing thermoplastics, if you have just five or 10 main print parameters and want to explore, say, five levels of each, a factorial design can result in millions of possible combinations of settings to print," says Sara Abdollahi, a Ph.D. student in biomedical engineering.

The combinations become even more daunting when exploring an experimental material whose print characteristics are unknown, she added.

However, the EGO model can be used to lessen the challenge of the combination. By combining an expert's scientific judgment with efficient search algorithms, EGO significantly reduces the time and energy required to find combinations that yield optimal 3-D prints for experimental materials.

The EGO model comprises the following three steps:

- An initial set of parameters is selected by human experts giving the algorithm the boundaries for search.

- Then, a hill climbing algorithm searches within those boundaries for promising combinations of those parameters, resulting in a "local optimum."

- Lastly, the expert evaluates the local optimum and decides whether to alter the search process by adding new parameters or continue to search within the existing boundaries.

The same process is repeated until an ideal solution is found and this method can extend beyond the 3-D printing of soft materials for a variety of engineering processes.